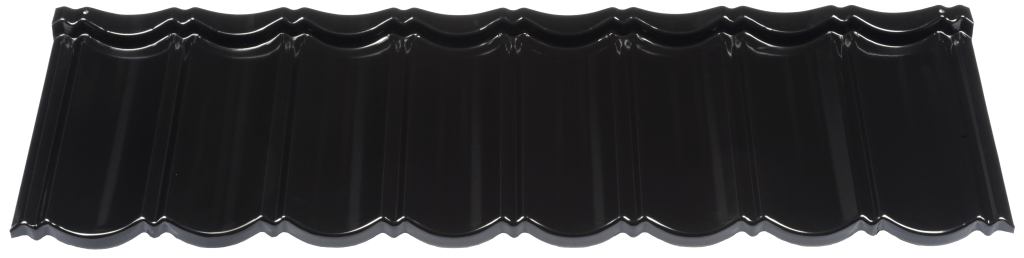

Introducing the worlds most advanced roof tile, Powder Coated X-BOND.

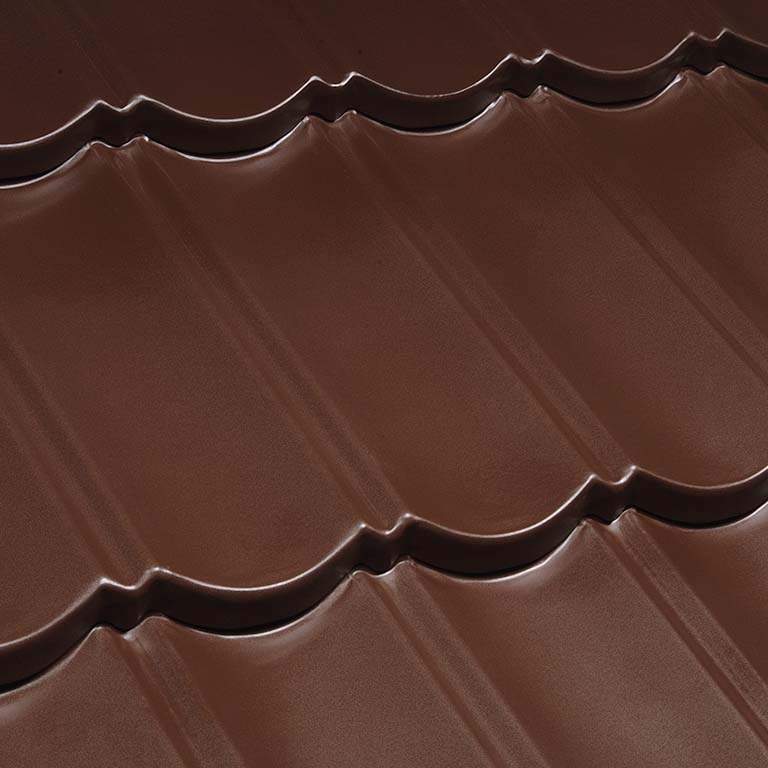

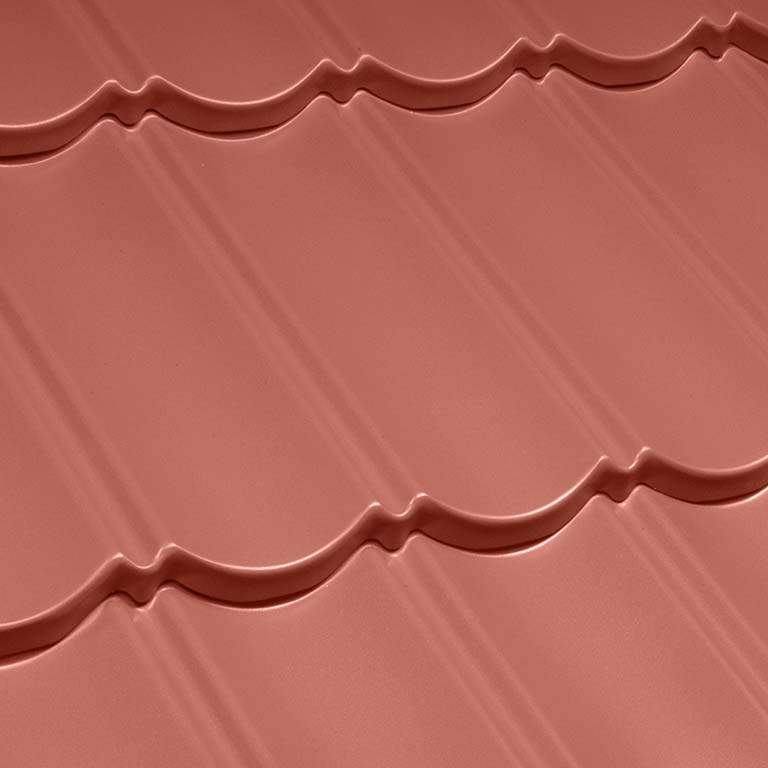

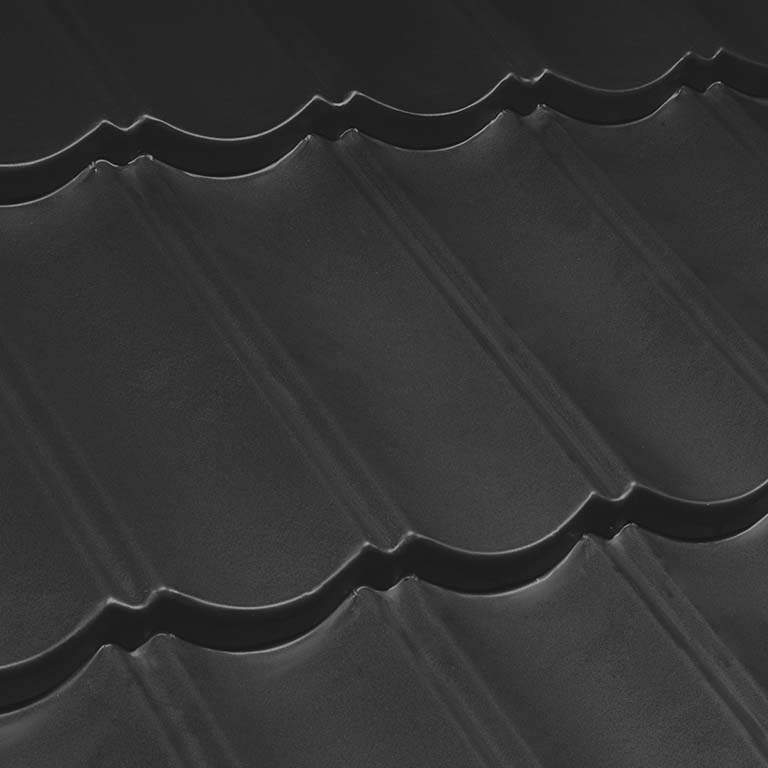

Powder Coating is used to create a harder finish that is tougher than conventional paint. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is applied as a dry powder, electrostatically fused to the steel and then cured under heat.

Because powder coating does not have a liquid carrier, it can produce thicker coatings than conventional liquid paint without running or sagging. The process is difficult, but X-BOND has perfected the technique to create an even, tough and smooth finish.

The specially developed lacquer that gives X-BOND its super-high gloss finish is the market’s strongest powder lacquering – Z-series™. This provides:

X-BOND Powder Coated Tile is a multi-layered solution. A strong Aluzinc steel plate primed and powder coated with a super strong Z-series™ powder lacquering. This has been adapted to meet our own requirements and the result is an absolutely top-class product. This procedure is a new, advanced and groundbreaking technology.

Beware of fake tiles. They might look like X-BOND, but they’re not made with the same high-grade raw materials. They are usually a false economy – that is, they start off being cheap to buy, but end up costing more than Genuine X-Bond due to all the maintenance and repairs they require.

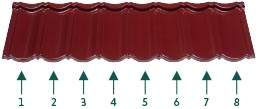

Our X-Bond profile has 8 “pans”. These are the valleys between each peak (see below). Fake tiles will generally have less than 8 sides, usually 5 or 6.

The answers to many common questions can be found in our brochure. If you haven’t found them here or wish to find you nearest Genuine X-Bond distributor, please continue to use this contact form.